Contributing to a Resource-Recycling Society

Environment (E)

- Long-Term Environmental Vision and Environment 2029V

- Environmental Management

- Responding to Climate Change

- Responding to Water Risks

- Contributing to a Resource-Recycling Society

- Contributing to a Society in Harmony with Nature

- Appropriate Chemical Substance Management

- Environmental Communication

- Environmentally Friendly Products

Shareholders and Investors, Suppliers and Other Trade Partners, Employees, Global Environment

Basic Approach

In recent years, the importance of sustainable resource circulation has grown significantly due to the need to reduce environmental impact and prevent resource depletion. Consequently, companies are increasingly expected to adopt advanced circular economy practices by minimizing waste and utilizing recycled and sustainable materials.

At the Sumitomo Riko Group, we utilize both natural resources, such as rubber and minerals, as well as petroleum-based materials like synthetic rubber and chemicals. In response to these societal challenges, we are committed to evolving our traditional 3R (Reduce, Reuse, Recycle) initiatives and advancing towards more sophisticated circular business practices that promote sustainable operations.

At the Sumitomo Riko Group, we utilize both natural resources, such as rubber and minerals, as well as petroleum-based materials like synthetic rubber and chemicals. In response to these societal challenges, we are committed to evolving our traditional 3R (Reduce, Reuse, Recycle) initiatives and advancing towards more sophisticated circular business practices that promote sustainable operations.

Efforts to Reduce Waste

At Sumitomo Riko Group, we continuously strive to reduce defects and improve yield while also engaging in the recycling of uncured rubber and other materials as part of our efforts to reduce waste.

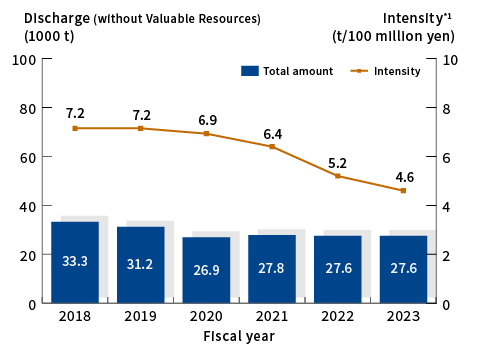

Waste Generation (Excluding Recoverables, Sumitomo Riko Group)

FY2024 Target: 2% reduction in intensity change rate compared to FY2022

In fiscal year 2024, the Sumitomo Riko Group achieved a 3.5% reduction in waste generation, excluding recoverable materials, compared to FY2022. Additionally, the waste intensity for FY2024 has decreased by 17.9% over the same period.

FY2024 Target: 2% reduction in intensity change rate compared to FY2022

In fiscal year 2024, the Sumitomo Riko Group achieved a 3.5% reduction in waste generation, excluding recoverable materials, compared to FY2022. Additionally, the waste intensity for FY2024 has decreased by 17.9% over the same period.

*The denominator used to calculate the intensity is net sales (after eliminating internal transactions) within the aggregation scope.

Example of Waste Reduction

At Sumitomo Riko Komaki Plant, we previously treated the shot blast dust generated during the surface treatment process of anti-vibration rubber products as industrial waste. However, by establishing markets for its sale as a valuable resource, we have significantly reduced both disposal costs and waste output.

(Waste reduction: 169 tons per year; cost savings: 5.735 million yen per year)

(Project submitted for the Sumitomo Riko 2025 Environmental Conservation Examples Awards)

(Project submitted for the Sumitomo Riko 2025 Environmental Conservation Examples Awards)

Efforts to Reuse Unwanted Items

Since 2022, Sumitomo Riko has been operating an internal exchange platform called the Sumitomo Riko Eco-Flea Market, allowing for the reuse of unwanted office supplies, equipment, and tools. This initiative reflects the spirit of mottainai (a Japanese term that expresses a sense of regret over waste), aiming to reduce waste and optimize the use of limited resources. By facilitating the transfer of these items to departments and subsidiaries in need, it also contributes to cost savings on new purchases.

(FY2024: 285 items exchanged)

(FY2024: 285 items exchanged)

Efforts to Recycle Waste

Sumitomo Riko is committed to achieving a circular economy by promoting the recycling of raw materials, including rubber, resin, and urethane waste. As part of this initiative, we are partnering with the biotechnology company LanzaTech to research and develop innovative technologies for producing rubber materials from waste.

Related Information

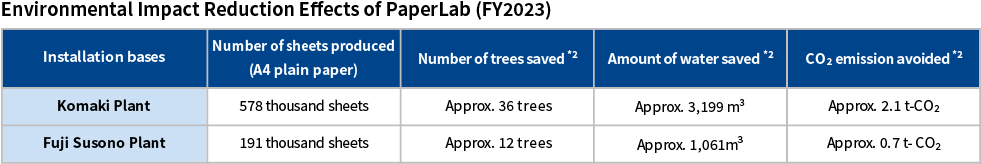

Example of Copy Paper Recycling

Since 2017, Sumitomo Riko has utilized the in-office dry papermaking system, PaperLab, to promote environmental conservation and enhance document security. This innovative device enables us to produce recycled paper from used paper, ensuring the safe handling of confidential documents while optimizing paper resources. Additionally, compared to conventional copy paper, it helps reduce environmental impact by decreasing wood usage, CO2 emissions, and water consumption.

The recycled paper is used for employee business cards and notepads, and is also donated to local municipalities, schools, and community organizations, highlighting our commitment to community connections. These initiatives are managed by our special subsidiary, SumiRiko Joyful Co., Ltd.*1, which provides employment opportunities for individuals with disabilities.

The recycled paper is used for employee business cards and notepads, and is also donated to local municipalities, schools, and community organizations, highlighting our commitment to community connections. These initiatives are managed by our special subsidiary, SumiRiko Joyful Co., Ltd.*1, which provides employment opportunities for individuals with disabilities.

*1 SumiRiko Joyful Company Limited: A special subsidiary established in November 2013 to promote the employment of people with disabilities and contribute to society.

*2 Calculated by Epson based on the number of recycled paper produced by Sumitomo Riko.

*2 Calculated by Epson based on the number of recycled paper produced by Sumitomo Riko.

Related Information

Related Information

Efforts to Expand Sustainable Material Use

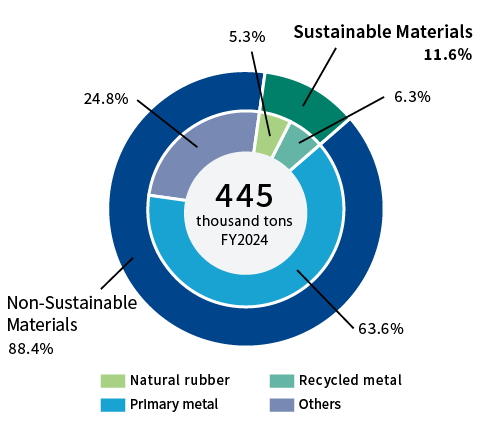

At the Sumitomo Riko Group, we define sustainable materials as those containing a combined total of at least 25% recycled materials and biomass components. To promote their use, we have begun evaluating current usage and exploring suitable materials for adoption starting in 2024.

Sustainable Material Ratio (Sumitomo Riko Group)

2029V Target: Sustainable material ratio of 20% or more

The sustainable material ratio for the Sumitomo Riko Group in FY2024 was 11.6%.

2029V Target: Sustainable material ratio of 20% or more

The sustainable material ratio for the Sumitomo Riko Group in FY2024 was 11.6%.

Efforts to Reduce Plastic Use

Discontinuation of PET Bottle Beverage Sales at Global Headquarters

—Efforts to Address Marine Pollution Caused by Plastic Waste—

Sumitomo Riko has initiated efforts to address the issue of marine plastic waste by discontinuing the sale of PET bottled beverages and transitioning to alternatives such as aluminum cans. At our Global Headquarters in Nagoya, we are aiming for zero usage of PET bottled beverages. Previously, we used an average of 780 PET bottles per month, totaling approximately 10,000 bottles annually. By eliminating this usage, we expect to reduce CO2 emissions by 80 grams per 500 ml PET bottle, resulting in an anticipated annual reduction of about 748 kg. In addition to discontinuing bottled beverages, we are promoting the use of in-house tea dispensers and encouraging employees to utilize personal reusable bottles.

This initiative began in FY2019 at our Global Headquarters, followed by the introduction of PET bottle-free vending machines at our Saitama Plant in FY2021 and at the SumiRiko Yamagata site in FY2022. By 2030, the target year for achieving the SDGs, we are aiming to phase out the sale of PET bottled beverages across all domestic locations and transition to canned products and other alternatives.

—Efforts to Address Marine Pollution Caused by Plastic Waste—

Sumitomo Riko has initiated efforts to address the issue of marine plastic waste by discontinuing the sale of PET bottled beverages and transitioning to alternatives such as aluminum cans. At our Global Headquarters in Nagoya, we are aiming for zero usage of PET bottled beverages. Previously, we used an average of 780 PET bottles per month, totaling approximately 10,000 bottles annually. By eliminating this usage, we expect to reduce CO2 emissions by 80 grams per 500 ml PET bottle, resulting in an anticipated annual reduction of about 748 kg. In addition to discontinuing bottled beverages, we are promoting the use of in-house tea dispensers and encouraging employees to utilize personal reusable bottles.

This initiative began in FY2019 at our Global Headquarters, followed by the introduction of PET bottle-free vending machines at our Saitama Plant in FY2021 and at the SumiRiko Yamagata site in FY2022. By 2030, the target year for achieving the SDGs, we are aiming to phase out the sale of PET bottled beverages across all domestic locations and transition to canned products and other alternatives.

Future Issues and Responses

Recognizing the diverse regulations surrounding waste management and landfill disposal across different countries, the Sumitomo Riko Group strives to achieve effective resource utilization. We aim to reduce waste generated from our production processes through our 3R initiatives while minimizing our reliance on incineration and landfill disposal. Additionally, we promote the efficient use of Earth’s resources by recovering energy from waste and developing biochemical recycling technologies.

Furthermore, in pursuit of a circular economy, we are focused on selecting renewable materials and designing structures that enable the easy separation of different materials. This approach supports the establishment of production processes that facilitate resource circulation.

Furthermore, in pursuit of a circular economy, we are focused on selecting renewable materials and designing structures that enable the easy separation of different materials. This approach supports the establishment of production processes that facilitate resource circulation.