Appropriate Management of Chemical Substances

Shareholders and Investors, Suppliers and Other Trade Partners, Employees, Global Environment

Basic Approach

The Sumitomo Riko Group uses a variety of chemical substances, including raw materials for products, sub-materials used in production processes, and CFCs used in air conditioning equipment.

Chemical substances can have a negative impact on the global environment by causing soil and groundwater contamination through the disposal of products containing them, or by being released into rivers and the atmosphere through leakage or evaporation during production processes.

Meanwhile, regulations on chemical substances are being tightened year by year, especially in Europe. Therefore, we are promoting safe and secure products manufacturing by strengthening our efforts to properly manage chemical substances, including the selection of chemical substances to be used, the establishment of management systems, and training for employees.

Chemical substances can have a negative impact on the global environment by causing soil and groundwater contamination through the disposal of products containing them, or by being released into rivers and the atmosphere through leakage or evaporation during production processes.

Meanwhile, regulations on chemical substances are being tightened year by year, especially in Europe. Therefore, we are promoting safe and secure products manufacturing by strengthening our efforts to properly manage chemical substances, including the selection of chemical substances to be used, the establishment of management systems, and training for employees.

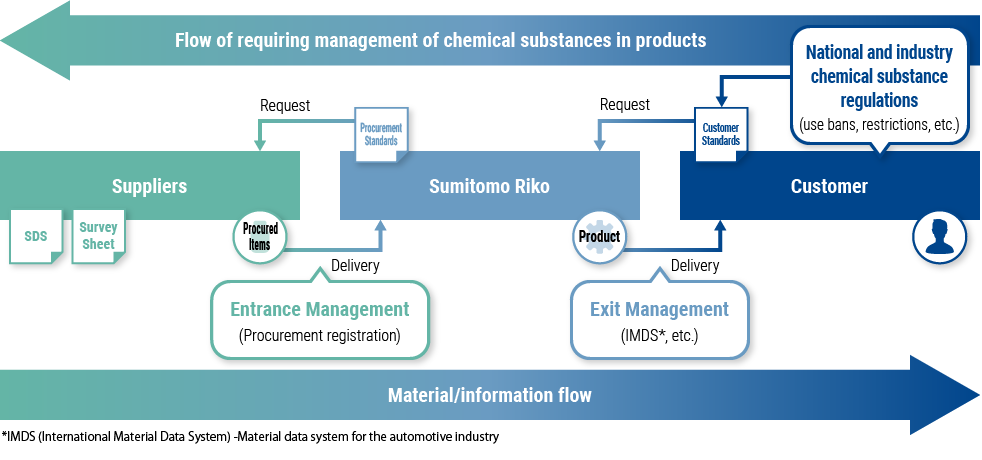

Chemicals Management in the Supply Chain

Sumitomo Riko manages chemical substances contained in our products throughout the supply chain.

In order to deliver products that meet the laws and regulations of each country and the standards of our customers, we use the chemical substance management system to control chemical substances contained in products during product design, material procurement, and our manufacturing processes. We stick to the "Selection and use of materials that meet legal regulations and customer requirements" and allow "No contamination or by-production of prohibited substances".

In order to deliver products that meet the laws and regulations of each country and the standards of our customers, we use the chemical substance management system to control chemical substances contained in products during product design, material procurement, and our manufacturing processes. We stick to the "Selection and use of materials that meet legal regulations and customer requirements" and allow "No contamination or by-production of prohibited substances".

Compliance with Overseas Chemical Substance Regulations

Sumitomo Riko exports materials, parts, and products to overseas Group production bases.

With the cooperation of our suppliers and importers, we are appropriately complying with regulations such as the REACH Regulation in Europe, China's New Regulations on the Environmental Management Registration of Chemicals*1, and Regulations on the Registration and Management of Hazardous Chemicals*2 and TSCA*3 in the United States.

*1 Measures for Environmental Management Registration of New Chemical Substances: Regulations on chemical substance registration in China

*2 Measures for Registration Administration of Hazardous Chemicals: Regulations for the management of hazardous substances in China

*3 TSCA: Regulations on chemical registration and hazardous substance management in the U.S.

With the cooperation of our suppliers and importers, we are appropriately complying with regulations such as the REACH Regulation in Europe, China's New Regulations on the Environmental Management Registration of Chemicals*1, and Regulations on the Registration and Management of Hazardous Chemicals*2 and TSCA*3 in the United States.

*1 Measures for Environmental Management Registration of New Chemical Substances: Regulations on chemical substance registration in China

*2 Measures for Registration Administration of Hazardous Chemicals: Regulations for the management of hazardous substances in China

*3 TSCA: Regulations on chemical registration and hazardous substance management in the U.S.

Management of Chemical Substances in Purchased Products

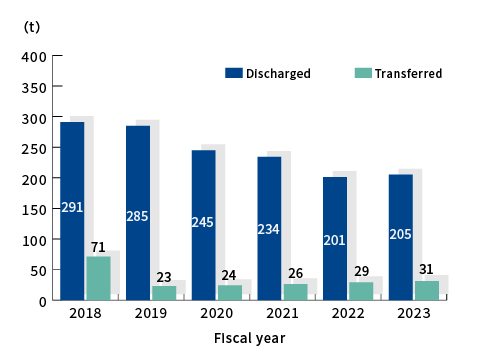

Emissions and Transfers of PRTR-controlled Substances

The Sumitomo Riko Group provides rubber and plastic products such as automotive parts, office equipment parts, and industrial products which are manufactured using raw materials containing various chemical substances. In order to minimize the various risks of chemical substances, we are striving for appropriate management in each of the following areas: prevention of pollution in local communities, ensuring workplace safety, and compliance with customer requirements for our products. In Japan, we monitor and control chemical substances in accordance with the PRTR Law.

Establishment and Operation of Substances to be Controlled

In order to prevent the release of regulated substances, Sumitomo Riko manages chemical substances in accordance with and in consideration of the laws and regulations of each country, mainly the European ELV Directive*4, RoHS Directive*5, REACH Regulation*6, domestic laws and regulations, GADSL*7, and IEC62474*8, as well as customer requirements. Specifically, we provide safe and secure products by thoroughly implementing the roles of each department and management and operation methods.

*4 ELV Directive: End-of-life vehicle (ELV) regulations in Europe (EU member states)

*5 RoHS Directive: The Restriction of the use of certain Hazardous Substances in electrical and electronic equipment in Europe

*6 REACH Regulation: Regulation on registration of chemical substances and management of hazardous substances in Europe

*7 GADSL: Global Automotive Declarable Substance List

*8 IEC62474: International controlled substances for the electrical and electronic industry

*4 ELV Directive: End-of-life vehicle (ELV) regulations in Europe (EU member states)

*5 RoHS Directive: The Restriction of the use of certain Hazardous Substances in electrical and electronic equipment in Europe

*6 REACH Regulation: Regulation on registration of chemical substances and management of hazardous substances in Europe

*7 GADSL: Global Automotive Declarable Substance List

*8 IEC62474: International controlled substances for the electrical and electronic industry

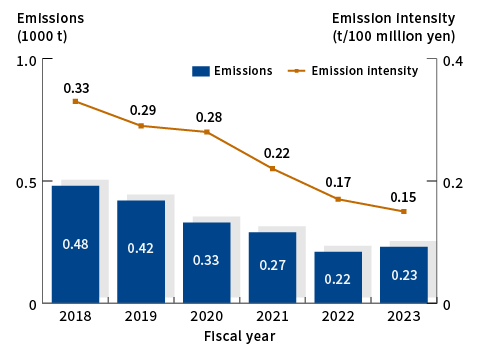

Efforts to Reduce Air Pollutants

VOCs*9 emitted into the atmosphere react with ultraviolet rays of sunlight, causing photochemical oxidants and suspended particulate matter. Of the raw materials used by our group, VOCs contained in adhesives mainly used for bonding rubber to metal fittings, rubber glue for hoses, and anti-rust paint for metal fittings are released into the atmosphere as they dry.

Therefore, we are working to reduce losses in adhesive processing machines by developing spray guns with high paint coverage and to reduce atmospheric emissions by reducing the use of VOCs through the use of water-based paints and other measures. We will continue our efforts and work with suppliers on new themes, such as the use of water-based adhesives.

Therefore, we are working to reduce losses in adhesive processing machines by developing spray guns with high paint coverage and to reduce atmospheric emissions by reducing the use of VOCs through the use of water-based paints and other measures. We will continue our efforts and work with suppliers on new themes, such as the use of water-based adhesives.

VOC emissions (Sumitomo Riko)

*9 VOC: Volatile Organic Compounds

*10 The scope of aggregation is Sumitomo Riko.

*11 Denominator of intensity is net sales (after elimination of internal transactions).

*12 Figures are based on the "Voluntary Action Plan for VOC Emission Reduction" of the Japan Rubber Manufacturers Association.

*10 The scope of aggregation is Sumitomo Riko.

*11 Denominator of intensity is net sales (after elimination of internal transactions).

*12 Figures are based on the "Voluntary Action Plan for VOC Emission Reduction" of the Japan Rubber Manufacturers Association.

VOC/Vulcanized Gas Treatment Equipment Management

VOC/Vulcanized gas treatment equipment is directly connected to production facilities, and there is a risk of production stoppage due to malfunctions such as "fire" or "exceeding emission limits due to breakdowns." We have prepared a guidebook for each of our bases that outlines precautions to be taken in the design and operation of this treatment equipment, and are working to raise awareness of these issues. In order to prevent the recurrence of recent VOC/vulcanized gas treatment equipment malfunctions, the guidebook includes examples of such malfunctions, their presumed causes, and preventive measures, which will lead to improvement in function.

Case Studies

Examples of VOC, vulcanization, and other emission control measures at overseas bases

Tokai Rubber (Jiaxing) Co., Ltd. (China)

①VOC Reduction Measures

In order to comply with stricter laws and regulations on VOC emissions in various countries, the Sumitomo Riko Group is reducing the amount of VOCs used and introducing combustion-type and absorption-type VOC treatment equipment at its bases in China, the United States, Poland, and other countries that have strict regulations on the concentration of VOCs released into the atmosphere.

Tokai Rubber Moldings (Tianjin) Co., Ltd. (China)

②Vulcanized Gas Measures

In China, the Central ecological and environmental protection inspection in 2016 initiated stricter environmental regulations and many companies were punished. Our group companies were also strongly required by the authorities to comply with NMHC (non-methane hydrocarbon) emission concentrations generated during rubber mixing and vulcanization, and we have successively introduced dedicated vulcanization gas treatment equipment that uses combustion methods and photocatalyst to meet the standards.

Soil and Groundwater Remediation

We have been systematically and continuously purifying groundwater contaminated by the past use of chlorinated solvents at the Komaki Plant, Matsusaka Plant, and Saitama Plant, and have reported the results to the government.

Case Studies

Komaki Plant

Since June 2001, we have been conducting the purification and monitoring at the Komaki plant using the pumped water aeration method. The concentration of contaminants has been decreasing sequentially and the purification effect has been recognized.

In FY2015, we additionally implemented purification using the anaerobic bioremediation, and are now proceeding with purification using the pumped water aeration method.

In FY2015, we additionally implemented purification using the anaerobic bioremediation, and are now proceeding with purification using the pumped water aeration method.

Matsusaka Plant

Since December 2005, we have been conducting the purification and monitoring at the Matsusaka plant using the pumped water aeration method. The concentration of contaminants has been decreasing sequentially and the purification effect has been recognized.

Saitama Plant

Since March 2007, we have been conducting the purification and monitoring at the Saitama plant using the pumped water aeration method. The concentration of contaminants has been decreasing sequentially and the purification effect has been recognized. We are also attempting purification by anaerobic bio-method, and have conducted it three times in 2007, 2017, and 2019 to promote purification.

Proper Management of Ozone-Depleting Substances

To protect the ozone layer and prevent global warming, we are promoting the control of CFC emissions into the atmosphere and the use of natural refrigerants. The amount of leakage in FY2022 based on the Fluorocarbon Emissions Control Act was 35t- CO2. We are managing operation through periodic inspections and proper disposal and collection in accordance with the law. We will continue to systematically renew equipment and reduce the use of fluorocarbons. In addition, we were awarded a rank A in the JRECO*13 CFC measure rating for FY2022.

*13 JRECO: Japan Refrigerants and Environment Conservation Organization

*13 JRECO: Japan Refrigerants and Environment Conservation Organization

Proper Storage of PCB Equipment

Polychlorinated biphenyl (PCB), which are nonflammable, chemically stable, and have high electrical insulation properties, have been used by our group in high-voltage transformers and capacitors. However, the enactment of the Stockholm Convention (POPs Convention) and the laws and regulations of various countries have resulted in a general ban on the manufacture and use of PCBs, requiring strict storage management and systematic waste disposal.

The Sumitomo RIko Group has been aware of the waste and has been systematically promoting proper waste disposal in accordance with the laws and regulations of each country, as well as storing the waste appropriately. With the completion of the disposal of highly concentrated PCB waste at the Matsusaka Plant in the spring of 2020, all disposal of highly concentrated PCB waste in Japan has been completed.

The Sumitomo RIko Group has been aware of the waste and has been systematically promoting proper waste disposal in accordance with the laws and regulations of each country, as well as storing the waste appropriately. With the completion of the disposal of highly concentrated PCB waste at the Matsusaka Plant in the spring of 2020, all disposal of highly concentrated PCB waste in Japan has been completed.

Response to Asbestos

Asbestos has been widely used in building materials and equipment components as a material with excellent heat and fire resistance, insulation, and sound insulation properties. However, the relationship between asbestos and health hazards has been scientifically clarified, and its use is now regulated or prohibited in many countries including Japan.

In 2017, our group conducted a reexamination of asbestos use in buildings and other facilities, and confirmed that there was no problem.

We have promptly taken measures such as containment and enclosure for newly identified materials and objects, and are taking appropriate management and treatment measures. In addition, we have prepared a countermeasure guidebook that outlines the proper management of asbestos and precautions to be taken when repairing or removing asbestos, which is used as an educational material.

In 2017, our group conducted a reexamination of asbestos use in buildings and other facilities, and confirmed that there was no problem.

We have promptly taken measures such as containment and enclosure for newly identified materials and objects, and are taking appropriate management and treatment measures. In addition, we have prepared a countermeasure guidebook that outlines the proper management of asbestos and precautions to be taken when repairing or removing asbestos, which is used as an educational material.

Future Issues and Responses

In order to comply with chemical substance regulations, which are becoming stricter year by year, and which differ from country to country and customer to customer, traceability from purchased raw materials to shipped products and emissions is important.

We will expand our current database of purchased raw materials for shipped products and build a database that allows us to collectively manage all shipped products, thereby creating a system that will allow us to quickly switch to new regulations.

We will expand our current database of purchased raw materials for shipped products and build a database that allows us to collectively manage all shipped products, thereby creating a system that will allow us to quickly switch to new regulations.