Sumitomo Riko's automotive products provide further comfort as well as the safety and security to drivers and passengers.

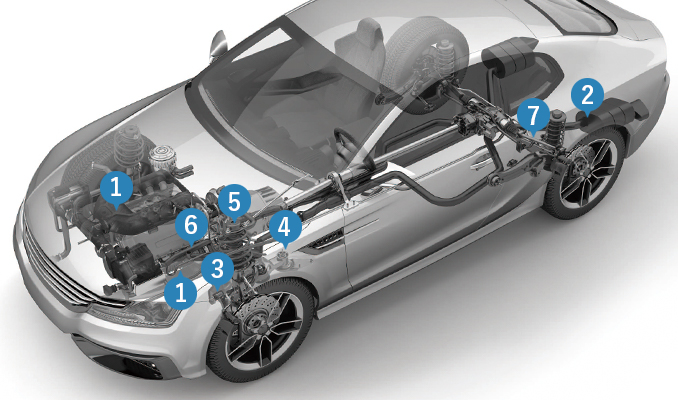

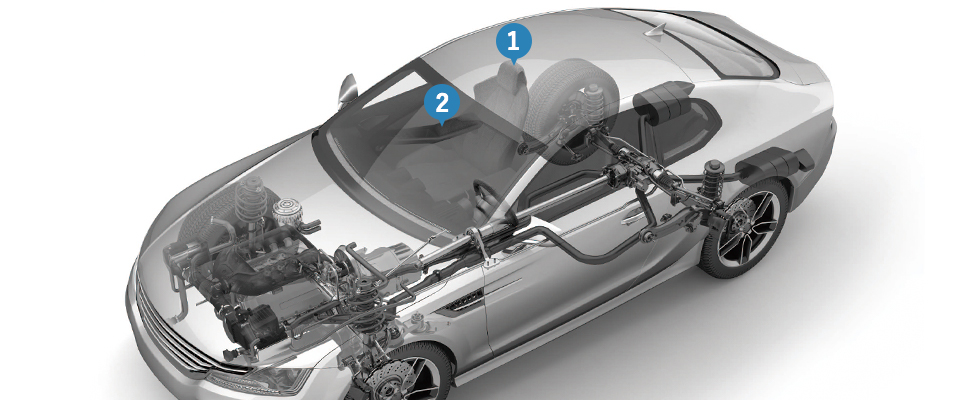

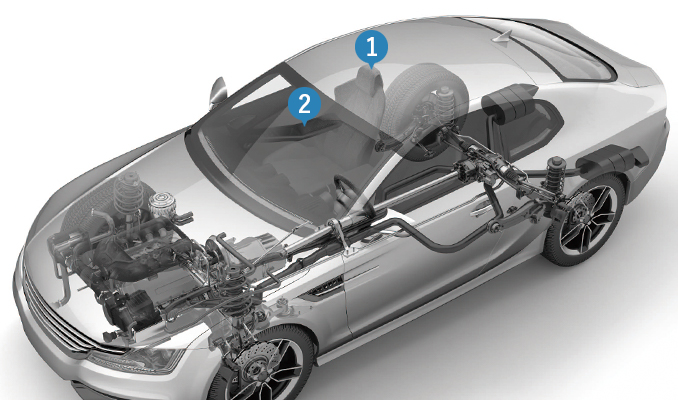

We are the world's top supplier* of anti-vibration rubber products that reduce vibration and noise caused by the engine and road surface.

Our wide-ranging products include automotive hoses for which we have the largest market share in Japan*, sound controlling & insulation products and interior equipment, such as engine covers and seats.

Through our global development and supply network covering five key regions, we are a stable source of consistently high-quality products for automotive manufacturers worldwide.

*Estimate by Sumitomo Riko

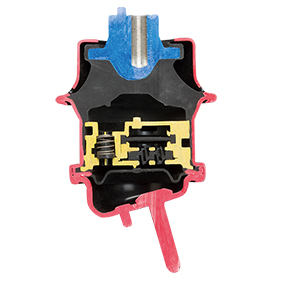

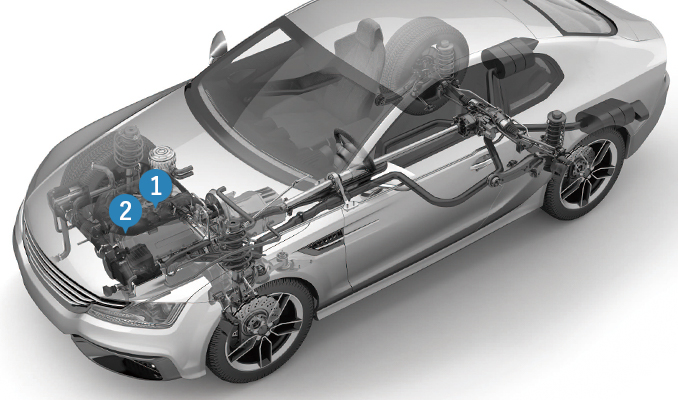

Sumitomo Riko's anti-vibration rubber products use rubber developed using our polymer materials technology, boasting flexibility, damping, and reliability, efficiently absorbing the vibrations from the engine and road surface to help contribute to a comfortable vehicle space.

Our heat-resistant rubber, an achievement of our high-polymer materials technology, delivers twice the heat-resistance of conventional mounts for long-lasting reliability. This contributes to long-term reliability.

Appropriately tuned, adaptive hydraulic engine mounts reduce the vibration generated by engines, contributing to both comfort and stable handling.

Our rubber materials endowed with twice the durability of conventional materials contribute to improved reliability and product downscaling.

Sealing the insides of rubber bushes with liquid for greater damping force and an optimal spring constant realizes both a smooth ride and stable handling.

Our products designed by exploiting the characteristics of glass fiber-reinforced resins are robust and lightweight, helping improve automotive fuel efficiency.

The shape design in combination with meticulous material selection to exploit key material characteristics delivers gains in performance and reliability. These easily recyclable, lightweight products have excellent environmental credentials.

These high-performance devices are optimized for engines which comply with environmental regulations. Real-time modulation of the spring constant and phase realizes a quiet ride in a wide range of conditions.

Installed in automotive subassemblies, devices which control vibrational eigenvalues suppress vibration to deliver more comfortable and quieter driving.

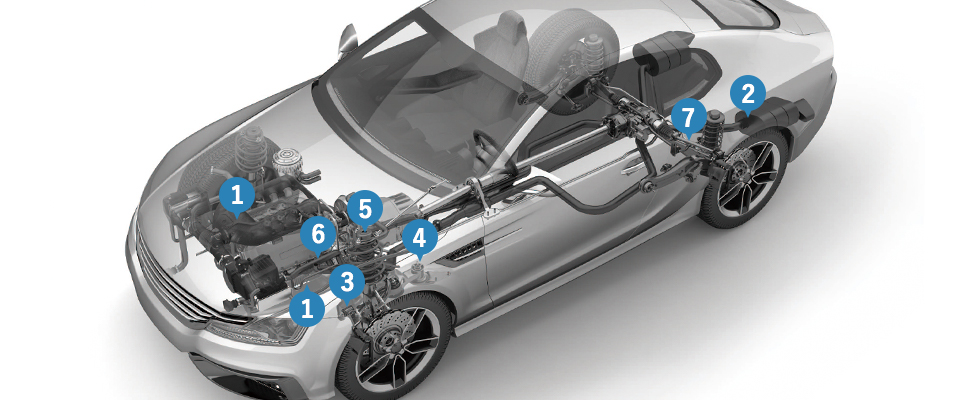

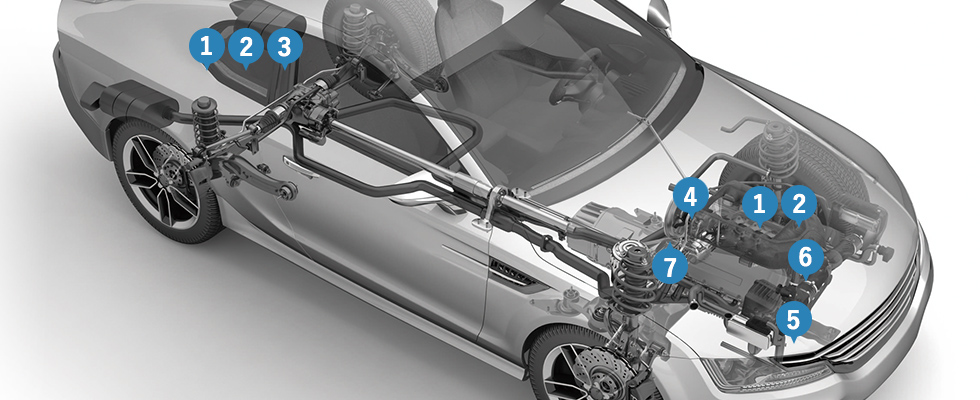

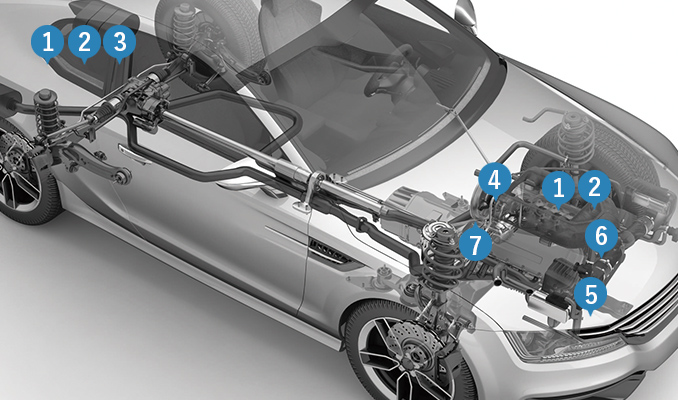

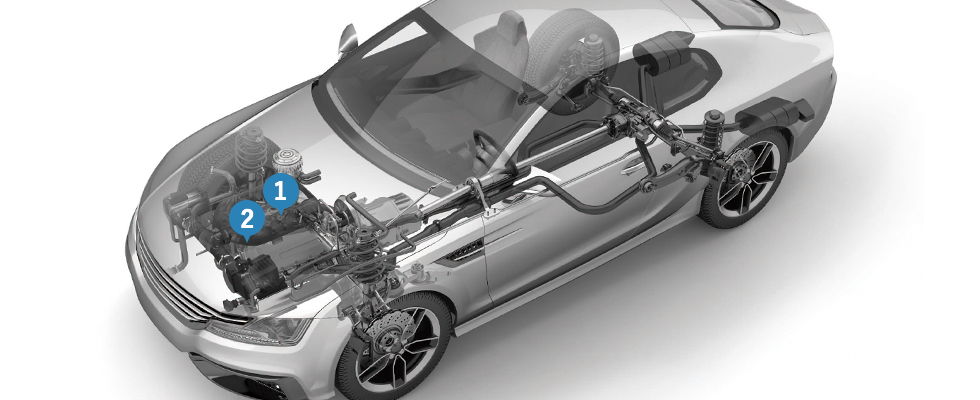

Sumitomo Riko automotive hoses run the length and breadth of the inside of vehicle chassis and are prized for their technology which combine rubber and resin.

They are used in many parts of the vehicle from around the engine to around the fuel tank due to their superior heat resistance, impact and vibration absorption and light weight properties.

Starting with “CASE*”, we think this is a major opportunity for great change in the automotive industry, and we will create new technologies and products that are suited to electrification and environmental regulations.

*C : Connected, A : Autonomous, S : Shared & Services, E : Electric

These products are mainly used around the engine and fuel tank, so require the use of materials with extremely good fuel resistance and durable structures. They are used in extremely severe environments where flexibility is required.

This product is mainly used around the engine and fuel tank. These resin hoses have low permeability and are made up of multiple layers of polymer materials, complying with the world's strictest gasoline evaporation regulations.

These are mainly found around the gasoline tank, repeatedly absorbing and releasing gasoline vapor. They comply with the world's strictest gasoline evaporation regulations.

We have developed the polymer materials technology to make these hoses extremely heat resistant. The product line-up includes heat-resistant turbo air hoses for attachment to ultra-high-temperature turbochargers.

These water line hoses include radiator and heater hoses. We use polymer materials technology to make them extremely heat resistant.

This product is expected to be highly heat-resistant due to the extreme heat in the environment it is used. It maximizes the performance of automatic transmission systems and contributes to the fuel efficiency of the vehicle. It is used in circuits that maintain transmission fluids at a constant temperature.

These hoses are used in refrigerant circulation systems for automobile air conditioning. Advanced technology is used to attach aluminum fittings to both ends of a flexible hose.

Hydrogen hoses are used to transport hard to seal small gaseous matter at high pressure. Installed in fuel cell electric vehicles (FCEV), these hoses require a high level of reliability and durability to ensure that hydrogen is not leaked outside the vehicle under any circumstances.

There are many sources of noise in an automobile, including engine.

Sumitomo Riko's sound controlling & insulation products shut out these noises and keep the inside of the cabin quiet.

Our original urethane is used for the engine cover due to its heat resistant and sound absorption and insulating properties, realizing a high degree of noise reduction even on the engine parts with high temperatures.

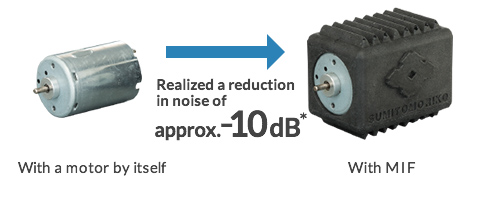

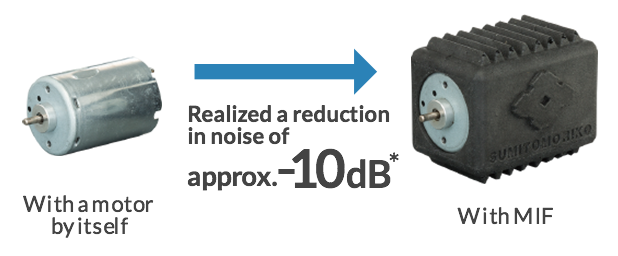

In addition, with the increasing demand for materials that can cut down on motor noise while also alleviating the damage caused by heat, Sumitomo Riko has successfully developed a sound reducing material that also conducts heat.

Installing a cover over the top of the engine reduces engine noise. We use materials with excellent heat-resistant and fire proofing properties to enable applications at extremely high temperatures. Optimized cover design also contributes to an improved engine compartment appearance.

These products fill airspace to reduce noise generated in gaps between the engine body and its peripheral equipment. Our mold-casting technology enables fitting into spaces with complex shapes.

"As a sound reducing material that also conducts heat, through our exclusive compounding technology, we have been able to achieve a material that has between 10 and 50 times higher thermal conduction properties than general sound proofing urethanes. This material has a wide range of possible applications, and we expect to see it in a variety of household appliances in the future."

*16V constant voltage motor Measured at a distance of 100 mm

Inside equipment in automobiles directly contacts the body of the user, so apart from the obvious requirements for safety, it is also important that the equipment satisfies the five senses. We manufacture interior parts such as headrests and armrests that have a pleasant texture but also have excellent shock resistance.

Our interior equipment contributes to comfort and safety in the car. Our unique urethane material and comprehensive production capabilities covering the entire manufacturing processes from cutting, sewing to integrated foaming result in products of consistently high quality.

Situated on the central parts of the doors on both sides, these provide comfort during the ride by proving a place to rest your arm. We adopt integrated molding techniques with outstanding design flexibility to provide products that provide comfort to drivers and passengers.

There are bundles of cables that carry power and signals and wire harnesses threaded throughout vehicles. There are about 500 waterproof seals used in each vehicle for the wire harnesses in and around the car, and we are able to provide a stable supply of these using our precision rubber molding technology and quality assurance system.

These waterproof connector seals are fastened to wire harnesses. Precision metal molding and liquid silicone molding technologies eliminate burrs and losses. In-line inspection assures the quality of all seals.

These seals provide waterproof effect to each wire in the connectors. They are produced by the fully automated processes, from the material feeding to inspection and packing.

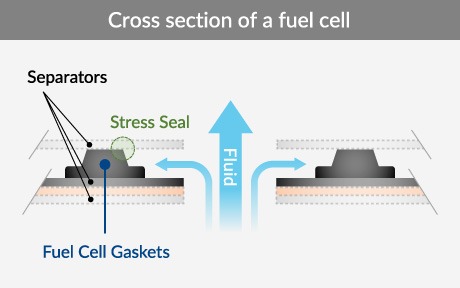

The FC stack contains hydrogen, oxygen and rubber sealing material to prevent water from leaking. The material is capable of sealing in temperatures ranging from sub-zero to 100℃ or higher and it contributes to the long-term stability and highly efficient power generation of FCEVs.