Appropriate Chemical Substance Management

Environment (E)

- Long-Term Environmental Vision and Environment 2029V

- Environmental Management

- Responding to Climate Change

- Responding to Water Risks

- Contributing to a Resource-Recycling Society

- Contributing to a Society in Harmony with Nature

- Appropriate Chemical Substance Management

- Environmental Communication

- Environmentally Friendly Products

Shareholders and Investors, Suppliers and Other Trade Partners, Employees, Global Environment

Basic Approach

The Sumitomo Riko Group utilizes a variety of chemical substances, including those found in raw materials for our products, manufacturing aids, and alternative refrigerants for air conditioning systems. While these chemicals are essential to our operations, improper handling can pose risks to human health and the environment by contaminating soil, air, and water. Consequently, regulations governing the use and disposal of chemicals are becoming increasingly stringent, especially in Europe.

In response to these growing regulations, we are taking proactive steps to mitigate these risks. We have established guidelines for managing chemical substances in compliance with the regulations of each country, ensuring that our raw materials are free from prohibited substances and promoting proper management through employee training. Through these initiatives, we are committed to producing safe and reliable products.

In response to these growing regulations, we are taking proactive steps to mitigate these risks. We have established guidelines for managing chemical substances in compliance with the regulations of each country, ensuring that our raw materials are free from prohibited substances and promoting proper management through employee training. Through these initiatives, we are committed to producing safe and reliable products.

Management of Regulated Substances and Material Sourcing

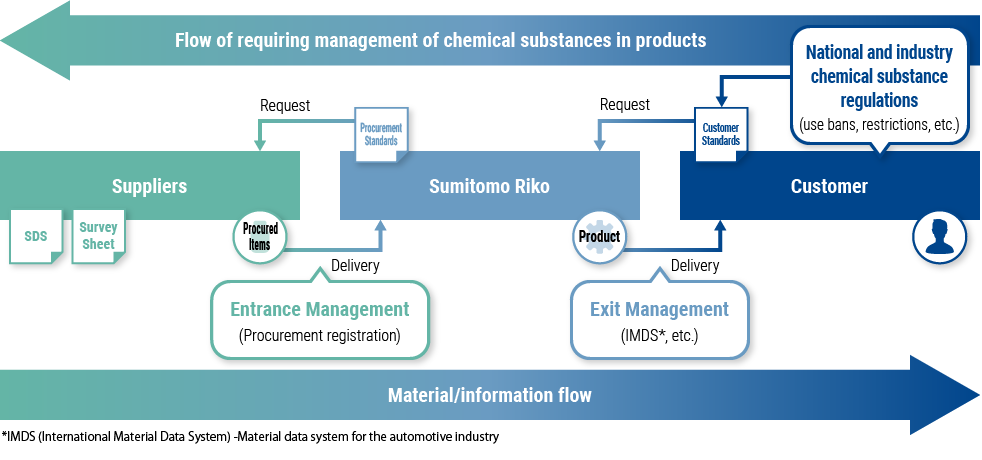

Global Procurement Standards and Management of Chemical Substances in Products

The Sumitomo Riko Group operates in 20 countries worldwide, providing products used across various markets. To comply with both the legal regulations of each country and the chemical substance standards set by our customers, we define the chemical substances that are permissible for our use and establish procurement guidelines accordingly. We communicate these standards to our suppliers to ensure that prohibited substances are not used and to prevent contamination of products caused by any by-products.

Additionally, we maintain a comprehensive database of chemical substance information for each raw material. For delivered products, we report information based on customer requirements, including through the International Material Data System (IMDS), while centrally managing this information within our organization. Through these initiatives, we are dedicated to delivering products that meet legal regulations and fulfill customer expectations.

Additionally, we maintain a comprehensive database of chemical substance information for each raw material. For delivered products, we report information based on customer requirements, including through the International Material Data System (IMDS), while centrally managing this information within our organization. Through these initiatives, we are dedicated to delivering products that meet legal regulations and fulfill customer expectations.

Material Selection and Export Management

Sumitomo Riko is committed to managing chemical substances to prevent the release of regulated materials. We define the approved raw materials for use within the organization in accordance with international standards such as GADSL*1 and IEC 62474*2, as well as the ELV Directive*3, the RoHS Directive*4, and the REACH Regulation*5 in Europe, along with domestic laws from each country and customer requirements.

Additionally, Sumitomo Riko exports materials, parts, and products to production bases around the world. We appropriately respond to the regulations in the regions we export to, including the REACH Regulation*5, China’s Measures for the Environmental Management Registration of New Chemical Substances*6, the Measures for the Registration and Management of Hazardous Chemicals*7, and the Toxic Substances Control Act (TSCA)*8 in the United States, with the cooperation of our suppliers.

*1 GADSL: Global Automotive Declarable Substance List. Identifies substances that automotive manufacturers must declare to control their use.

*2 IEC 62474: Standard for managing information about substances in electrical and electronic products, requiring manufacturers to declare specific substances.

*3 ELV Directive: End-of-Life Vehicles Directive. Sets requirements for recycling vehicles at the end of their life to reduce waste.

*4 RoHS Directive: Restriction of Hazardous Substances Directive. Limits specific hazardous materials in electrical and electronic products to protect health and the environment.

*5 REACH Regulation: Registration, Evaluation, Authorisation and Restriction of Chemicals. Ensures safe chemical use in the EU by requiring registration and information disclosure.

*6 Measures for the Environmental Management Registration of New Chemical Substances: Regulation for the registration of chemical substances in China.

*7 Measures for the Registration and Management of Hazardous Chemicals: Regulation for the management of hazardous substances in China.

*8 TSCA: Toxic Substances Control Act. Regulates chemical registration and management of hazardous substances in the U.S.

Additionally, Sumitomo Riko exports materials, parts, and products to production bases around the world. We appropriately respond to the regulations in the regions we export to, including the REACH Regulation*5, China’s Measures for the Environmental Management Registration of New Chemical Substances*6, the Measures for the Registration and Management of Hazardous Chemicals*7, and the Toxic Substances Control Act (TSCA)*8 in the United States, with the cooperation of our suppliers.

*1 GADSL: Global Automotive Declarable Substance List. Identifies substances that automotive manufacturers must declare to control their use.

*2 IEC 62474: Standard for managing information about substances in electrical and electronic products, requiring manufacturers to declare specific substances.

*3 ELV Directive: End-of-Life Vehicles Directive. Sets requirements for recycling vehicles at the end of their life to reduce waste.

*4 RoHS Directive: Restriction of Hazardous Substances Directive. Limits specific hazardous materials in electrical and electronic products to protect health and the environment.

*5 REACH Regulation: Registration, Evaluation, Authorisation and Restriction of Chemicals. Ensures safe chemical use in the EU by requiring registration and information disclosure.

*6 Measures for the Environmental Management Registration of New Chemical Substances: Regulation for the registration of chemical substances in China.

*7 Measures for the Registration and Management of Hazardous Chemicals: Regulation for the management of hazardous substances in China.

*8 TSCA: Toxic Substances Control Act. Regulates chemical registration and management of hazardous substances in the U.S.

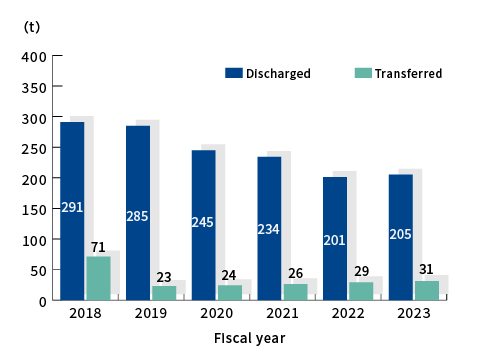

Management of PRTR-Controlled Substances

The Sumitomo Riko Group conducts proper management and reporting in accordance with the PRTR (Pollutant Release and Transfer Register) system, which requires the reporting of chemical substance emissions and transfers to regulatory authorities. This system is implemented in Japan and many other countries, and we accurately monitor the usage and emission levels of the relevant chemical substances, reporting them to the appropriate authorities.

Additionally, we have established an internal management system for chemical substances and are actively working to reduce emissions. Through these efforts, we not only comply with legal requirements but also reduce our environmental impact, thereby fostering trust within the communities we operate in.

Additionally, we have established an internal management system for chemical substances and are actively working to reduce emissions. Through these efforts, we not only comply with legal requirements but also reduce our environmental impact, thereby fostering trust within the communities we operate in.

Release and Transfer of PRTR-Controlled Substances (Sumitomo Riko)

Efforts to Reduce Air Pollutants

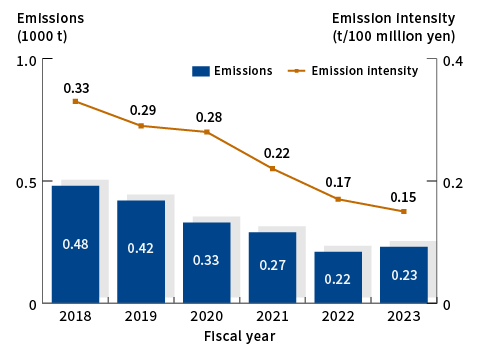

Volatile Organic Compounds (VOCs) released into the atmosphere react with ultraviolet rays from sunlight, leading to the formation of photochemical oxidants and particulate matter. Within the raw materials used by the Sumitomo Riko Group, VOCs are primarily found in adhesives used to bond rubber to metal fittings, as well as in rubber adhesives for hoses, and anti-corrosion coatings for metal parts, which release VOCs during the drying process.

To address this issue, we are committed to reducing VOC emissions by developing high-efficiency spray guns that minimize adhesive waste during application and by transitioning to water-based coatings to lower VOC usage. Moving forward, we will continue these efforts and collaborate with suppliers on new initiatives, including the further development of water-based adhesives.

To address this issue, we are committed to reducing VOC emissions by developing high-efficiency spray guns that minimize adhesive waste during application and by transitioning to water-based coatings to lower VOC usage. Moving forward, we will continue these efforts and collaborate with suppliers on new initiatives, including the further development of water-based adhesives.

VOC Emissions (Sumitomo Riko)

*The scope of the aggregation is Sumitomo Riko Company Limited.

*The denominator used to calculate the intensity is net sales (after eliminating internal transactions) within the aggregation scope.

*Figures are based on the Voluntary Action Plan for Reducing VOC Emissions of the Japan Rubber Manufacturers Association.

*The denominator used to calculate the intensity is net sales (after eliminating internal transactions) within the aggregation scope.

*Figures are based on the Voluntary Action Plan for Reducing VOC Emissions of the Japan Rubber Manufacturers Association.

Management of VOC and Vulcanization Gas Treatment Systems

The VOC treatment system and the vulcanization gas treatment system each pose a risk of exceeding emissions regulation limits in the event of a fire or operational failure. To address this risk, we have developed a comprehensive guidebook that outlines essential design and operational considerations for these systems. This guidebook is shared across all our locations to ensure a consistent understanding. Additionally, it includes examples of past incidents, their estimated causes, and corresponding corrective actions, which are utilized to prevent recurrence and enhance our continuous improvement initiatives.

Case Studies

Emission Control Measures for VOC and Vulcanization Gases

①VOC Reduction Measures

At the Sumitomo Riko Group, we are responding to the tightening of VOC emission regulations in various countries by reducing their usage and installing combustion-type and adsorption-type VOC treatment systems at locations with strict atmospheric discharge concentration standards, such as China, the United States, and Poland.

②Vulcanization Gas Control Measures

In China, the tightening of environmental regulations began with the Central Environmental Protection Inspection in 2016, resulting in penalties for many companies. In response, our group is gradually implementing treatment systems specifically designed for vulcanization gases, using combustion methods and photocatalytic oxidation to effectively manage non-methane hydrocarbons (NMHCs) emitted during the mixing and vulcanization of rubber.

Soil and Groundwater Remediation

At the Sumitomo Riko Group, we previously used chlorinated organic solvents to clean metal components. However, in the 1990s, concerns over soil and groundwater contamination, as well as health risks, including carcinogenicity, gained global attention, leading to stricter regulations. Consequently, we transitioned to water-based cleaning agents.

At sites where soil contamination has been confirmed, we promptly notify the authorities as required by law and work to remediate the affected areas. We implement methods such as excavation and soil replacement at locations where factories are no longer operational. At active sites, we conduct groundwater pumping, aeration, and anaerobic bioremediation, while continuously monitoring contaminant concentrations to assess the situation.

Sites with complete remediation include the Okayama Plant in Japan, where the land was sold after cleanup, and Sumiriko AVS in France. Ongoing remediation efforts are taking place at the Komaki Plant, Matsusaka Plant, and Saitama Plant, all located in Japan.

At sites where soil contamination has been confirmed, we promptly notify the authorities as required by law and work to remediate the affected areas. We implement methods such as excavation and soil replacement at locations where factories are no longer operational. At active sites, we conduct groundwater pumping, aeration, and anaerobic bioremediation, while continuously monitoring contaminant concentrations to assess the situation.

Sites with complete remediation include the Okayama Plant in Japan, where the land was sold after cleanup, and Sumiriko AVS in France. Ongoing remediation efforts are taking place at the Komaki Plant, Matsusaka Plant, and Saitama Plant, all located in Japan.

Proper Management of Ozone-Depleting Substances

At the Sumitomo Riko Group, we are actively promoting the reduction of ozone-depleting substances (ODS), such as chlorofluorocarbons (CFCs), and the adoption of natural refrigerants to both protect the ozone layer and mitigate global warming.

In the fiscal year 2024, the reported leakage amount, in accordance with the Fluorocarbon Emissions Control Act, was 64.1 tons of CO2 equivalent. We manage these substances through legally mandated periodic inspections and ensure proper recovery and disposal practices.

Going forward, we will continue to upgrade our equipment and strive to reduce ODS usage.

In the fiscal year 2024, the reported leakage amount, in accordance with the Fluorocarbon Emissions Control Act, was 64.1 tons of CO2 equivalent. We manage these substances through legally mandated periodic inspections and ensure proper recovery and disposal practices.

Going forward, we will continue to upgrade our equipment and strive to reduce ODS usage.

Proper Management of PCB Equipment

Polychlorinated biphenyls (PCBs), known for their non-flammability, excellent electrical insulation properties, and chemical stability, were once widely used in applications such as high-voltage transformers and capacitors. However, following the establishment of the Stockholm Convention (POPs Convention) and subsequent regulations in various countries, the manufacture and use of PCBs are largely prohibited.

The Sumitomo Riko Group has identified all relevant equipment and has implemented strict storage management and planned waste disposal in accordance with each country's regulations. With the completion of high-concentration PCB waste disposal at the Matsusaka Plant in spring 2020, all such waste disposal in Japan has now been completed.

The Sumitomo Riko Group has identified all relevant equipment and has implemented strict storage management and planned waste disposal in accordance with each country's regulations. With the completion of high-concentration PCB waste disposal at the Matsusaka Plant in spring 2020, all such waste disposal in Japan has now been completed.

Proper Management of Asbestos

Asbestos has historically been used in building materials and equipment due to its exceptional heat resistance, fireproofing capabilities, insulation properties, and soundproofing abilities. However, as our understanding of the health risks associated with asbestos has evolved, many countries, including Japan, have implemented regulations or outright bans on its use.

In 2017, the Sumitomo Riko Group conducted a thorough reassessment of asbestos use in buildings and facilities, confirming that no issues were present at that time. For any newly identified asbestos-containing materials and related items that emerged after the 2017 reassessment, we have promptly implemented measures such as containment and enclosure.

Furthermore, we developed a comprehensive guidebook outlining best practices for asbestos management and the precautions necessary during the repair and removal of structures or items containing asbestos. This guidebook serves as essential training material for our team.

In 2017, the Sumitomo Riko Group conducted a thorough reassessment of asbestos use in buildings and facilities, confirming that no issues were present at that time. For any newly identified asbestos-containing materials and related items that emerged after the 2017 reassessment, we have promptly implemented measures such as containment and enclosure.

Furthermore, we developed a comprehensive guidebook outlining best practices for asbestos management and the precautions necessary during the repair and removal of structures or items containing asbestos. This guidebook serves as essential training material for our team.

Future Issues and Responses

Chemical substance regulations are becoming increasingly stringent each year, with specific requirements and targeted substances varying by country and customer. To address these challenges, it is essential to ensure traceability from purchased raw materials to finished goods and ultimately to waste.

To this end, we are enhancing our database of purchased raw materials, which is currently under development, and this database will serve as the foundation for a new comprehensive database that includes finished goods. Additionally, we will establish a system capable of quickly responding to new regulations.

To this end, we are enhancing our database of purchased raw materials, which is currently under development, and this database will serve as the foundation for a new comprehensive database that includes finished goods. Additionally, we will establish a system capable of quickly responding to new regulations.