Environmentally Friendly Products

Environment (E)

- Long-Term Environmental Vision and Environment 2029V

- Environmental Management

- Responding to Climate Change

- Responding to Water Risks

- Contributing to a Resource-Recycling Society

- Contributing to a Society in Harmony with Nature

- Appropriate Chemical Substance Management

- Environmental Communication

- Environmentally Friendly Products

Shareholders and Investors, Suppliers and Other Trade Partners, Global Environment

Basic Approach

The Sumitomo Riko Group is committed not only to reducing the environmental impact of its business activities but also to addressing social challenges through the development of environmentally friendly products and technologies that comply with environmental regulations. These efforts are founded on the concept of Creating Shared Value (CSV), which seeks to balance corporate profits with contributions to society.

As part of this initiative, we are establishing a system to certify environmentally friendly products as 'Eco Products,' starting in fiscal year 2024, based on internally defined criteria. This initiative aims to enhance employee awareness of environmental issues and further promote the development of products that benefit society and the global environment.

As part of this initiative, we are establishing a system to certify environmentally friendly products as 'Eco Products,' starting in fiscal year 2024, based on internally defined criteria. This initiative aims to enhance employee awareness of environmental issues and further promote the development of products that benefit society and the global environment.

Products for New Energy Vehicles

In response to global warming, the development of environmentally friendly vehicles is accelerating worldwide. In this context, the Sumitomo Riko Group is advancing the design and production of products to tackle the challenges associated with new energy vehicles, such as battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs).

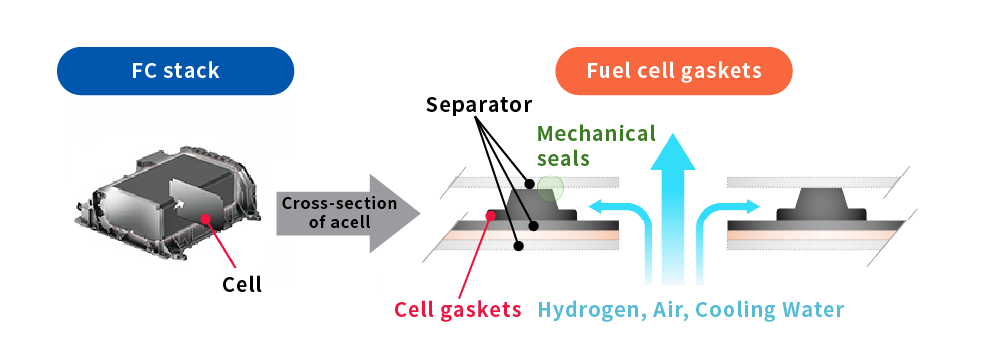

For BEVs, we manufacture components specifically engineered to control vibrations related to drive motors and enhance sound insulation. For FCEVs, we have developed a rubber sealing component known as the cell gasket for fuel cell stacks (FC stacks), which has been in continuous use since the launch of the world’s first mass-produced fuel cell vehicle, the MIRAI. Additionally, we have created a high-performance hydrogen hose that supplies hydrogen from the tank to the FC stack, which has been adopted in fuel cell trucks.

For BEVs, we manufacture components specifically engineered to control vibrations related to drive motors and enhance sound insulation. For FCEVs, we have developed a rubber sealing component known as the cell gasket for fuel cell stacks (FC stacks), which has been in continuous use since the launch of the world’s first mass-produced fuel cell vehicle, the MIRAI. Additionally, we have created a high-performance hydrogen hose that supplies hydrogen from the tank to the FC stack, which has been adopted in fuel cell trucks.

Products for BEVs: Anti-Vibration Rubber, Hoses, and Sound Insulation Products

Products for FCEVs: Cell Gaskets, Anti-Vibration Rubber, and Hoses

Related information

Non-Petroleum Products (Biohydrin Rubber)

Sumitomo Riko, in collaboration with Toyota Motor Corporation and Zeon Corporation, has developed bio-hydrin rubber. This innovative rubber incorporates plant-based materials and has the potential to reduce greenhouse gas (GHG) emissions by approximately 20% over its entire lifecycle—from production to disposal—compared to conventional petroleum-based hydrin rubber. Furthermore, it maintains quality and manufacturability that are comparable to its petroleum-based counterparts.

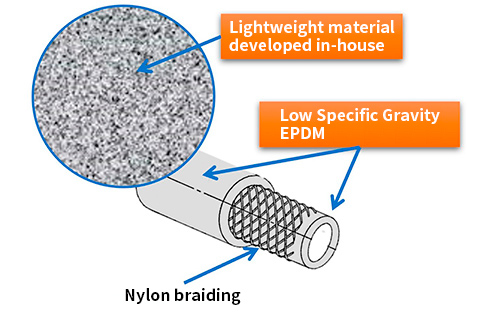

Automotive Fuel-Efficiency Improvement Product (Low-Density EPDM Hose)

Low-density EPDM (ethylene propylene diene rubber) hoses have been developed to reduce the weight of vehicle components. These hoses are suitable for a variety of water-based systems, including water bypass hoses and radiator hoses. While maintaining properties such as strength, durability, heat resistance, and electrical insulation comparable to conventional EPDM hoses, the new formulation incorporates lightweight reinforcing materials, resulting in an approximate weight reduction of 20%. By switching to our low-density EPDM hoses, vehicles can achieve a weight savings of about 1 kg* per unit.

*Based on proprietary calculations by Sumitomo Riko.

*Based on proprietary calculations by Sumitomo Riko.

Automotive Fuel-Efficiency Improvement Product (Resin Filler Neck Module)

We have replaced the filler piping that directs fuel into the fuel tank from metal to resin, achieving approximately a 40% weight reduction compared to conventional metal hoses. This lightweight design contributes to improved vehicle fuel efficiency.

Additionally, this resin filler neck module features excellent fuel permeability resistance (minimizing the likelihood of fuel seeping through the resin and rubber piping) and complies with environmental regulations.

Additionally, this resin filler neck module features excellent fuel permeability resistance (minimizing the likelihood of fuel seeping through the resin and rubber piping) and complies with environmental regulations.

VOC-Free Products (Water-Developable Photopolymer Flexo Plates)

Flexographic printing is a printing process that utilizes flexible rubber relief plates. AquaGreen® is a water-developable flexographic plate, while many competing products rely on solvents. This environmentally friendly printing plate is beneficial for both the planet and the workplace, offering high precision, exceptional productivity, and the added value of being waste liquid-free.

Energy-Saving Products (High-Transparency Heat Shielding and Insulating Film)

Refleshine® is a high-transparency window film designed for dual functionality: it suppresses solar heat inflow (heat shielding) and reduces indoor heat loss (insulation). These features help reduce energy consumption for air conditioning, contributing to lower GHG emissions. As a result, it has been adopted in railway vehicles and buildings.

Furthermore, our film utilizes advanced polymer technology to deliver excellent heat shielding while maintaining the visibility and scratch resistance required for automotive windows, making it suitable for applications such as front and side windows in vehicles.

Furthermore, our film utilizes advanced polymer technology to deliver excellent heat shielding while maintaining the visibility and scratch resistance required for automotive windows, making it suitable for applications such as front and side windows in vehicles.

Related information

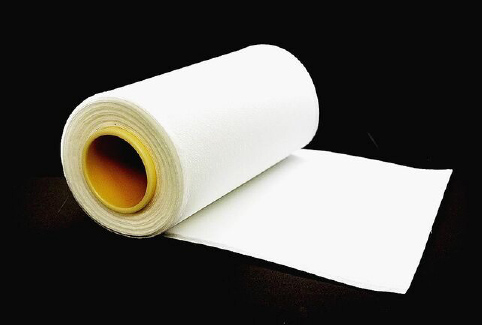

Insulation Material (Thin-Film High-Performance Insulation)

Finesulight® is a thin film material that provides excellent thermal insulation properties. We are actively exploring its applications in manufacturing sites, facilities, living spaces, and various products.

When applied around heat sources, Finesulight® enhances thermal efficiency in factories and facilities, reduces the load on air conditioning systems, and ultimately lowers energy consumption. This increased thermal efficiency leads to a significant reduction in CO2 emissions associated with business operations. By doing so, we support our customers' efforts toward carbon neutrality and contribute to the realization of a decarbonized society.

Finesulight® received the Aichi Invention Award in 2022, sponsored by Aichi Prefecture Institute of Invention and Innovation.

When applied around heat sources, Finesulight® enhances thermal efficiency in factories and facilities, reduces the load on air conditioning systems, and ultimately lowers energy consumption. This increased thermal efficiency leads to a significant reduction in CO2 emissions associated with business operations. By doing so, we support our customers' efforts toward carbon neutrality and contribute to the realization of a decarbonized society.

Finesulight® received the Aichi Invention Award in 2022, sponsored by Aichi Prefecture Institute of Invention and Innovation.

Related information

Related information