Safety and Health

Shareholders and Investors, Customers, Suppliers and Other Trade Partners, Employees

Safety and Health Activities

Policy

We are further strengthening our global safety activities to achieve "Zero Accidents (occupational, fire, and traffic accidents). To achieve “Zero Accidents”, we cannot achieve it without both “Safe People Fostering” and “Safe Organization/Safe Workplace Development.” We are building a safety culture to make each and every associate autonomous so that they can always be aware of safety and act accordingly.

Safety and Health Management

Based on the de facto standards that the Sumitomo Riko Group has cultivated over the years, we have clearly defined "Safety and Health Management Guidelines." We operate the GSSs (Global Safety Standards), which include various safety standards.

Safety Philosophy

Safety is our top priority for happiness of all employees and prosperity of the company. We confirm the safety before starting operations of the day.

10 Principles of Safety

- Always keep in mind that safety is our top priority.

- Have conviction that all kinds of injuries and occupational diseases are preventable.

- It is the responsibility of the company and individuals to establish, sustain, and improve the safe condition.

- The management has the direct responsibility to prevent injuries and occupational diseases.

- It is the basic responsibility of individuals in the society to follow the rules.

- Sufficient education and training must be provided to all employees to ensure safe operations.

- Safety and health audit in which all employees take part must be conducted to establish PDCA of the safety and health control system.

- Report and investigate all accidents as well as unsafe actions and conditions leading to accidents.

- All defects on safety and health must be remediated immediately.

- Cooperation and participation of all employees are inevitable to attain our zero-accident goal.

Promotion Structure

Involvement of Workers (Employees)

In addition to each of our activities, associates participate in decision-making at various Safety and Health conference bodies and committees at each of our bases as well as Safety and Health Patrols. At the work sites, we gather feedback from associates and utilize it to make improvements, “Collect and Reveal activities.”

Group-wide Activities

Building a Safe Organization

The Sumitomo Riko Group is promoting the creation of a safe organization at its domestic and overseas bases by promoting the early detection and improvement of unsafe behavior and unsafe conditions through daily workplace inspections by top management, including the base manager, and safety personnel.

Building a Safe Workplace

Our group promotes a safe workplace through the following activities.

(Occupational accident prevention) Eliminate unsafe conditions by keeping offices and manufacturing sites tidy and preventing contact between forklift trucks and people by separating them.

(Fire prevention) Eliminate ignition sources by inspecting, maintaining, and cleaning machinery.

(Workplace environment) Manage the workplace environment including chemical substances, heat, noise, etc.

(Occupational accident prevention) Eliminate unsafe conditions by keeping offices and manufacturing sites tidy and preventing contact between forklift trucks and people by separating them.

(Fire prevention) Eliminate ignition sources by inspecting, maintaining, and cleaning machinery.

(Workplace environment) Manage the workplace environment including chemical substances, heat, noise, etc.

Fostering Safe People

Our group establishes and implements GSS (Global Safety Standards), promotes audits to ensure compliance, the top management is engaged in safety dialogues to raise the safety awareness and knowledge of associates. In addition, we are promoting the “fostering of safe people” by improving each person's sensitivity to hazards through hazard prediction training.

Fire Prevention Activities

In-house fire prevention activities include establishing standards with fire prevention rules and promoting equipment inspections using thermography for early detection of electrical equipment in factories. In addition, the status of fire prevention measures is checked by top management through genchi-genbutsu (on-site) inspections of bases in Japan and overseas and through web-based instructions. The instructions are given to strengthen inspections of machinery, including information on accidents at other companies, and to eliminate combustible materials through 5S at work sites.

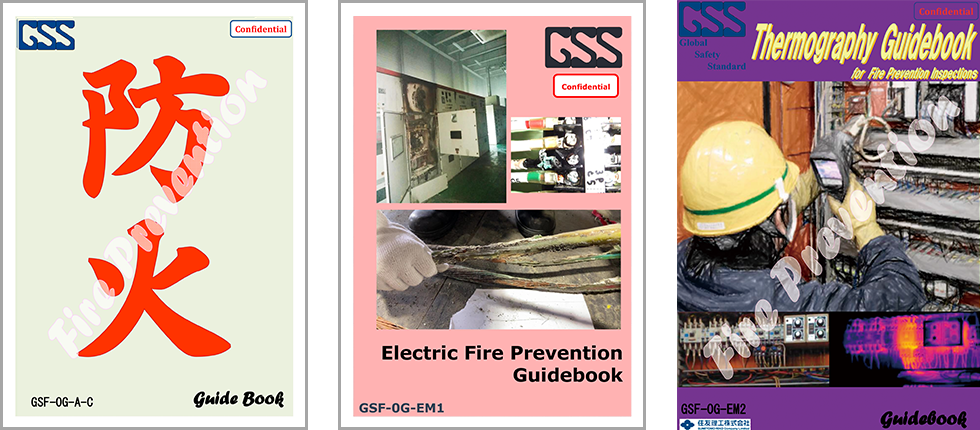

Traffic Safety

Our group also considers traffic accidents in Japan to be a major issue, and we share information on the locations of traffic accidents that have occurred on the way to and from work (traffic accident map) and conducts traffic safety training using VR and other methods.

In addition, we raise awareness of traffic-related issues by displaying awareness posters according to the season, and we promote the prevention of traffic accidents on a daily basis.

In addition, we raise awareness of traffic-related issues by displaying awareness posters according to the season, and we promote the prevention of traffic accidents on a daily basis.

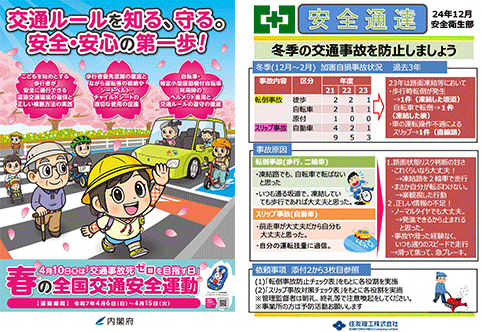

Chemical Substance Management

We have introduced a chemical substance management system to centrally manage chemical substances handled in the company, including SDS management, applicable laws and regulations, chemical substance risk assessment, and searches for banned substances in products. Thus, we have established an environment that enables associates to effectively implement chemical substance management.

Chemical Substance Management Instruction

We published guidebooks for the safe handling of chemical substances to improve the knowledge of our employees.

- Basic knowledge section: Improvement of knowledge of all associates

- Laws and regulations section: Improvement of legal expertise of chemical substance managers and practitioners (Commentaries on laws and regulations of the Industrial Safety and Health Act, Poisonous and Deleterious Substances Control Act, and Fire Service Act)