This exhibition is held as one of the exhibitions within “Smart Energy WEEK” and is one of the world's largest hydrogen energy exhibitions, featuring manufacturing technologies, components, materials, equipment, and systems for hydrogen and fuel cells, which are being researched and developed to realize a decarbonized society.

At this exhibition, Sumitomo Riko Group will exhibit “Separator with both side gasket”, “Water electrolysis bipolar plate with both side gasket”, “Hydrogen hosefor FCEV (fuel cell vehicle)”, “Carbon separator for fuel cell”, “High durability sealing and high-speed production technology” as components related to hydrogen and fuel cells. In addition, “Battery Cooling Plate: Cool Fit Plate” and “Side Cooling System for Battery” will be exhibited as battery cooling components used in FCEVs and other vehicles.

| Exhibition Name | H2 & FC EXPO, Hydrogen & Fuel Cell Expo |

| Dates | February 19 (Wed.) - 21 (Fri.) |

| Venue | Tokyo Big Sight, East Hall |

| Booth No. | E2-14 |

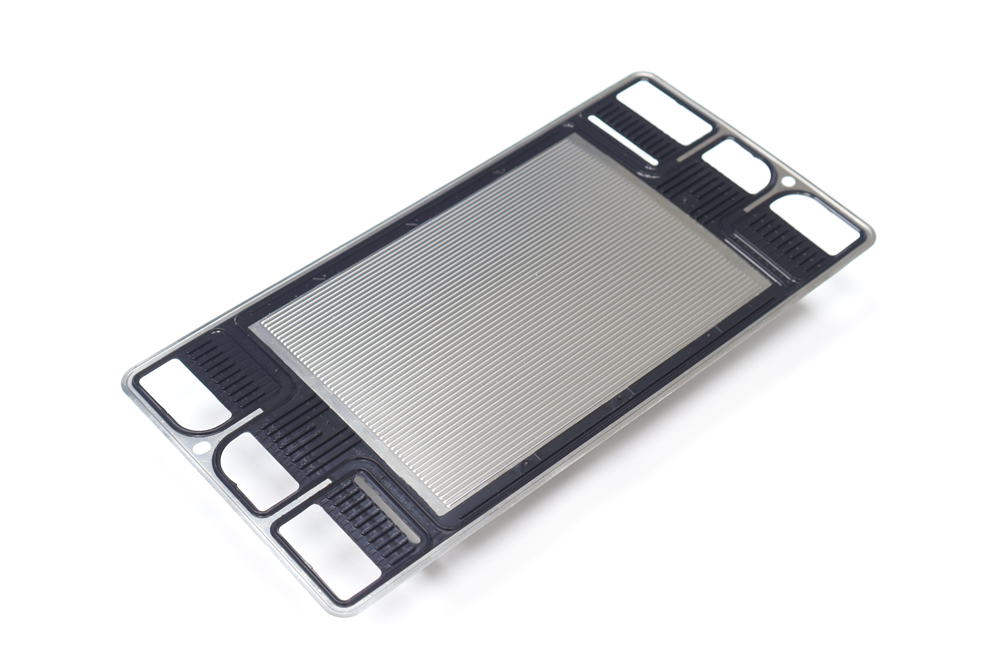

>>Separator with both side gasket

Using simultaneous front and back molding technology, the rubber sealing material (gasket) that prevents leakage of hydrogen, oxygen, and cooling water is integrated into a plate-shaped component called a separator. This integration eliminates the need for adhesion in the cellular process and contributes to cost reductions by reducing the total man-hours required.

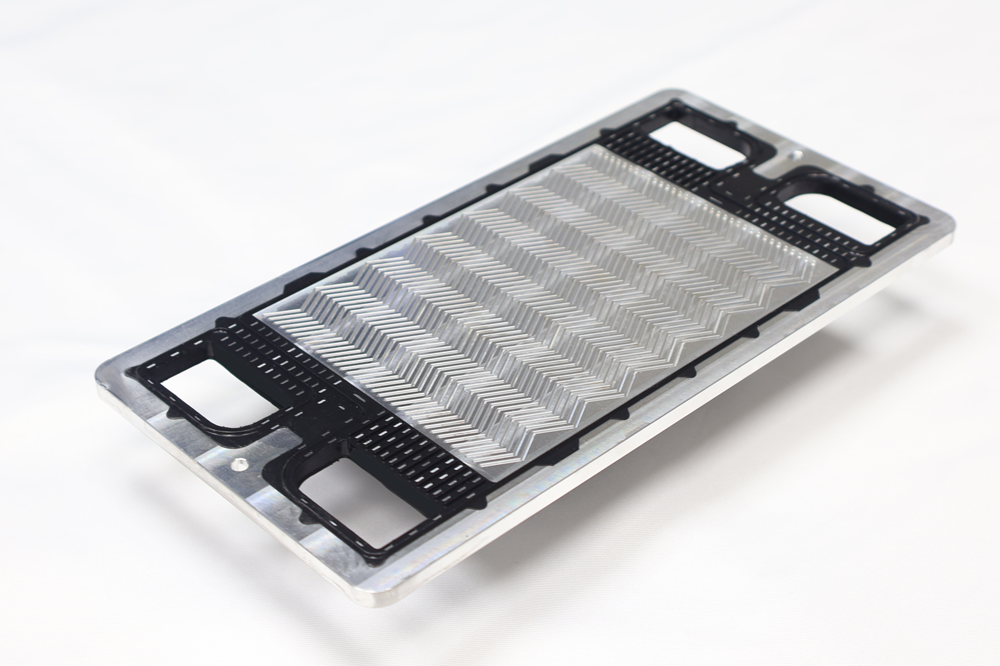

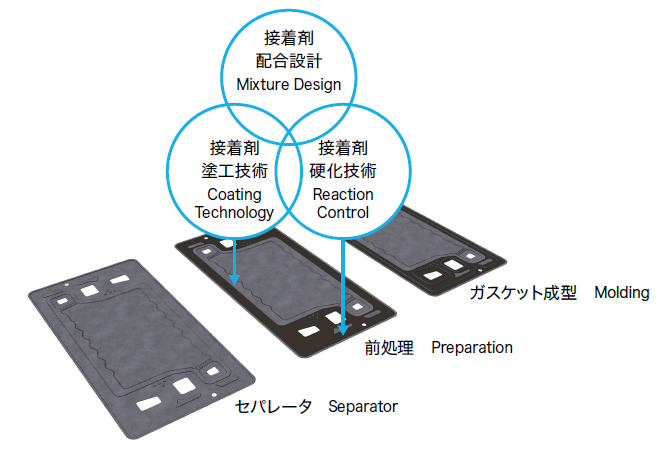

>>Water electrolysis separator with both side gasket

The separator with gasket integrated using simultaneous front and back molding technology realized a reduction in the number of parts required. The lip (three-dimensional) shape provides sealing performance even under high pressure, contributing to increased efficiency in water electrolysis systems, which require a high-pressure environment. The use of ethylene-propylene rubber (EPDM) as the material enables a design that is not affected by the type of electrolyte. In addition, the non-adhesive structure eliminates the need for adhesion processes, leading to cost reductions.

>>Our technology of high durability and productivity

This seal production technology has high durability against acidity, alkalinity, and oxygen and can be molded in less than one minute. The use of highly durable rubber makes it resistant to heat and elution, enabling stable bonding with a variety of materials and providing highly practical gaskets.

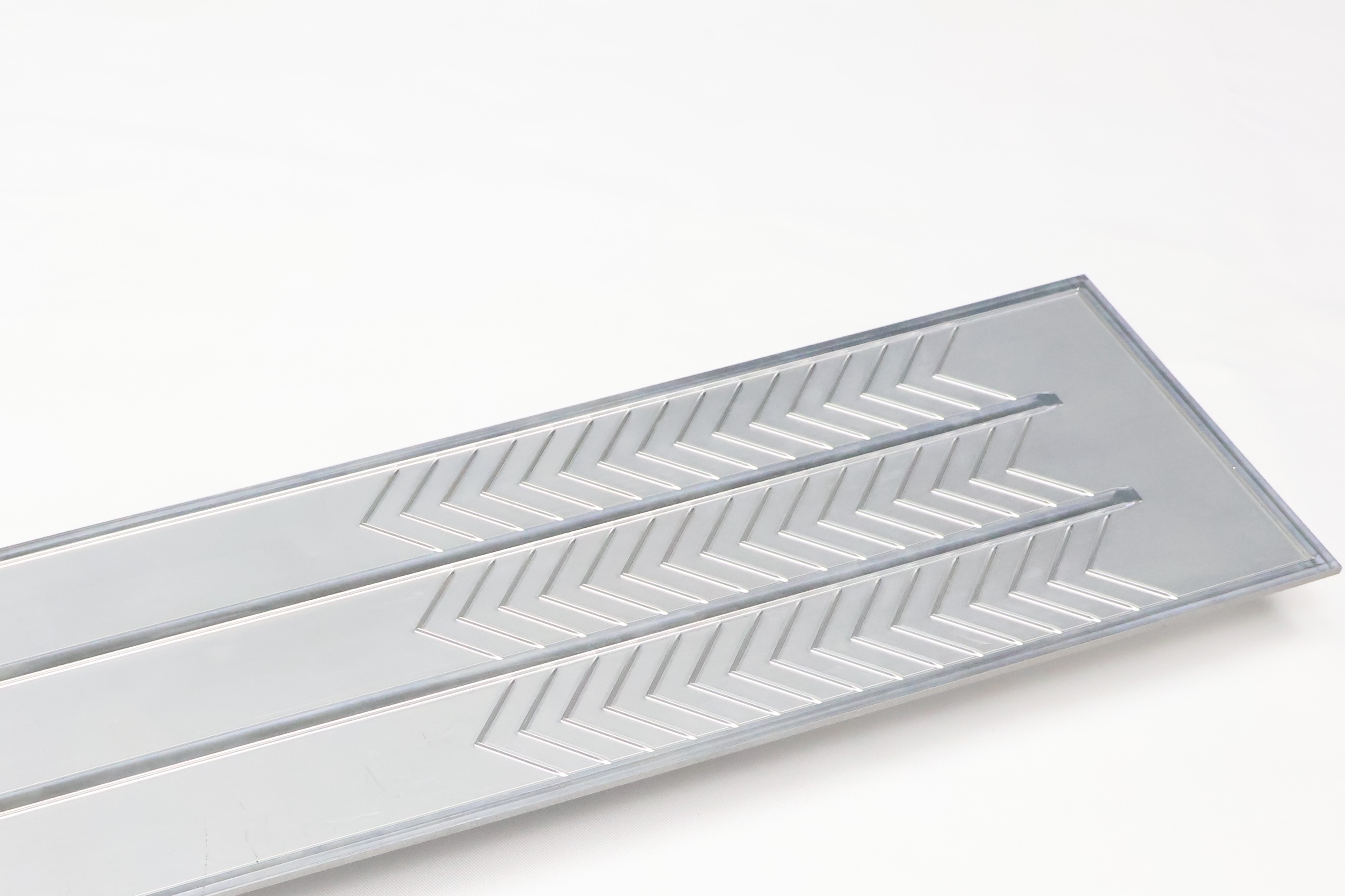

>>Carbon separator for fuel cells

This is a carbon separator made from our proprietary blend of carbon powder and thermosetting resin. The use of press molding eliminates the need for cutting of the flow path, thus reducing costs. In addition, the separator's thinner wall thickness enables weight reduction and high conductivity.

>>Hydrogen hose for FCEV

This hose supplies hydrogen filled in the hydrogen tank to the fuel cell stack. It meets the extremely high sealing requirements for hydrogen, which has an extremely small molecular weight. In addition, to convey hydrogen to the stack using high pressure, high pressure resistance of 10 MPa or higher is ensured.

Lower plate

>>Battery cooling plate: Cool Fit Plate™

This product cools batteries, enabling efficient cooling of the bottom of the battery (the upper side of the flow path) and furthermore, achieving temperature uniformity of the battery. It features protrusions in the parallel flow paths, which generate vortices and agitate the fluid boundary layer, resulting in efficient cooling performance. Moreover, by placing the protrusions in the optimal locations, the cooling efficiency can be improved at any point, thereby reducing the temperature difference between different parts of the battery, which contributes to extending battery life.

>>Side cooling system for Battery

This cooling system integrates the functions of absorbing cell expansion/contraction and cooling the sides of the cell. The adhesion process with gaskets is not necessary due to the use of connecting holes. In addition, by forming the front and back flow channels with rubber, this product can absorb cell expansion/contraction and cool the sides of the cell at the same time.