Damper braces for vehicles

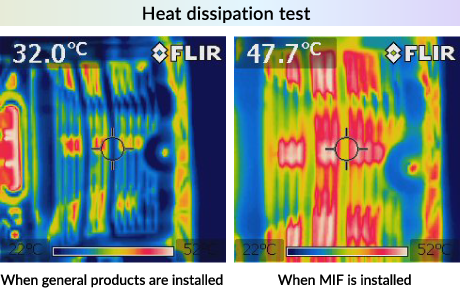

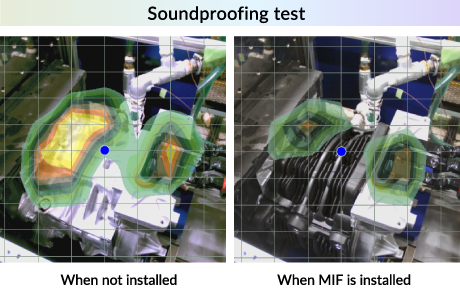

Damper braces contain “high damping special viscoelastic material” that absorb the heat energy transformed from the vibration energy and thermal energy utilizing our polymer materials technology. This can also be installed in limited and narrow spaces by utilizing its highly free design, a characteristic of rubber materials.