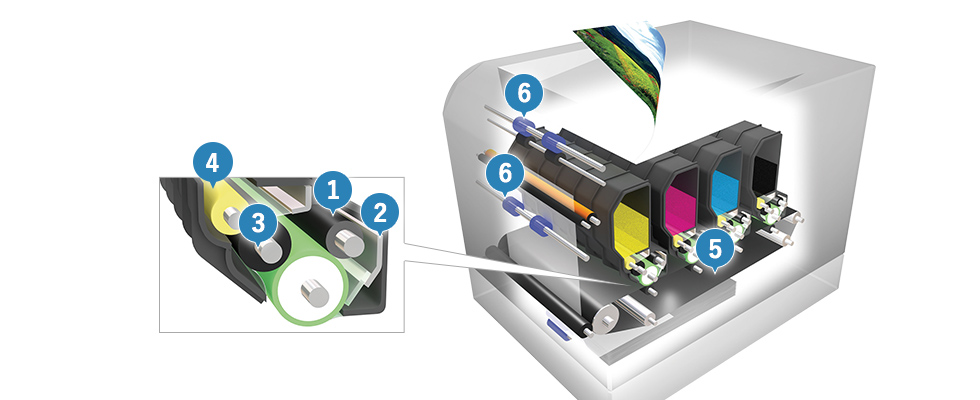

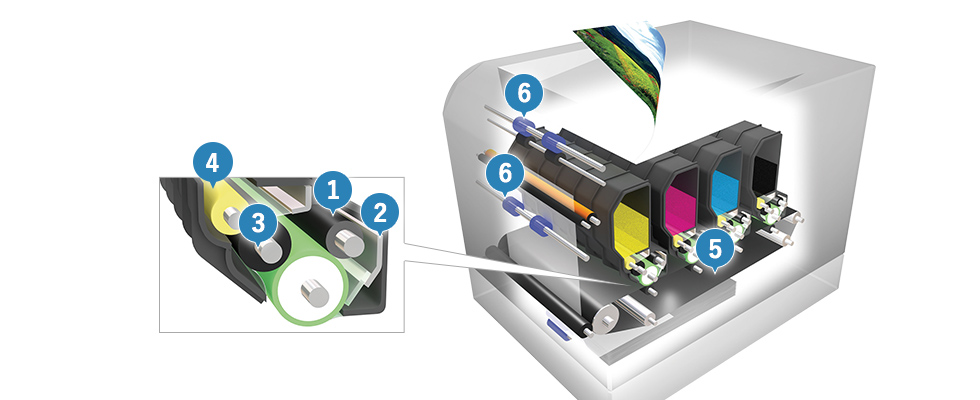

From charging rollers, which Sumitomo Riko was the first to develop and productize, through to cleaning blades and developer rollers, wherever you look in the vital parts of devices such as printers and copiers you will find Sumitomo Riko parts performing vital functions that influence the quality of the picture. We provide solutions to the advanced needs of modern society as IT becomes more important through our innovative formulation design technology, compounding technology to bring together different materials, and our precision processing technology.

Along with this, other important issues are the innovative technologies to build societies beneficial to both people and the earth with the burgeoning population putting pressures on resources and energy and causing conflicts, while concern over the global environment grows. At Sumitomo Riko we have been able to produce water-washable flexographic printing plates, a revolutionary concept that contributes to a reduced burden on the environment because organic solvents are not used in the production of the plates. We have been able to enter the environmental solutions field, including plate production systems, and we will continue to move into other business fields with our technologies.

Office equipment such as printers and copiers are indispensable in the modern world.

Sumitomo Riko has developed a great variety of functional parts, beginning with the charging rollers, by making the most of its innovative formulation design technology, compounding technology to bring together different materials, and precision processing technology, contributing to the improvements in performance in office equipment.

Our rubber rolls uniformly charge the surface of photoconductor drums. They are highly functional components with a decisive influence on image quality. We were the first in the world to develop and commercialize the charging rollers.

Cleaning blades remove toner that remains on photoconductor drums. Molding and adhesion of different materials—metal and urethane—are performed simultaneously. This micron-level, high-precision processing technology is our proprietary technology.

Molding and adhesion of different materials—metal and urethane—are performed simultaneously. This enables advanced electrical property control, dimensional accuracy, and high durability.

Sponge rollers uniformly supply and remove toner. Our processing technology realizes surface design for dimensional accuracy and high durability, thereby contributing to product differentiation.

These belts perform the essential function of generating full color images by superposing four-color toners. These seamless belts achieve uniform electrical properties over the entire surface and high durability.

These rollers precisely feed sheets of paper one sheet at a time. The combination of our proprietary urethane formulation technology and surface design molding prevents adhesion of paper dust to sheets of paper, thus helping ensure stable paper feeding.

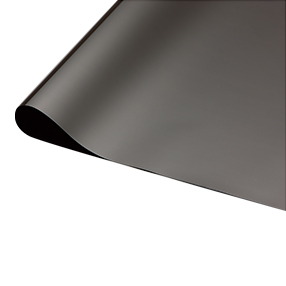

Flexographic printing enables you to use any type of ink or printing medium, and from an environmental perspective it is currently receiving a lot of attention.

Conventionally, the plates used were made of resin, and it was necessary to develop the plates with solvents. Sumitomo Riko used its compounding knowhow to develop a rubber plate that was compatible with flexographic printing. While image quality remains high, water based inks can be used meaning that the plates can be developed with just water, so they are kinder to the environment. We believe that this has the potential to become the new standard in the next generation of printing for flexible packaging, a market that is growing.

Flexographic printing is a printing method that uses flexible rubber plates. AquaGreen from Sumitomo Riko is a water-washable flexo printing plate (where other companies use solvents), meaning it is environmentally-friendly and gentle on those working with it. This is a printing plate with top environmental credentials that also provides high resolution and great productivity.