Sumitomo Riko Company Limited (Headquarters: Nakamura-ku, Nagoya-shi; President & CEO: Kazushi Shimizu) is delighted to announce that the Toyota Motor Corporation (“Toyota”, Head Office: Toyota-shi, Aichi; President and Representative Director: Akio Toyoda) has utilized our anti-vibration rubber, hoses, and sound controlling & insulation products for its electric car “bZ4X” (Battery Electric Vehicle: BEV) released on May 12. Based on the BEV-dedicated platform jointly developed by Toyota and Subaru Corporation (Head Office: Shibuya-ku, Tokyo; Representative Director of the Board, President and CEO: Tomomi Nakamura), the bZ4X is scheduled to be released in stages throughout the world, and we intend to take this opportunity to develop these products for other vehicles using this platform.

On this occasion, Toyota has decided to utilize our anti-vibration rubber, hoses and sound controlling & insulation products.

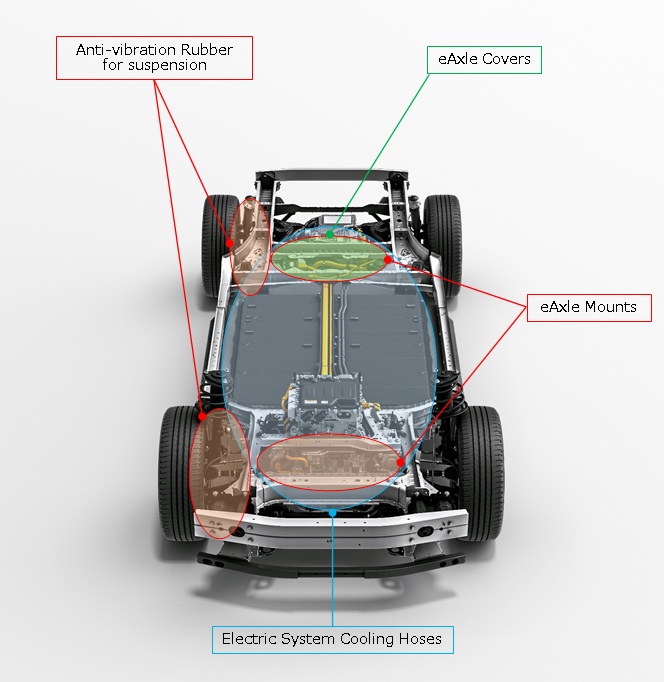

The anti-vibration rubber Toyota decided on was our “eAxle mount” developed especially for the “eAxle”, an electric drive module which integrates the electric motor, transaxle and inverter. This module is of such importance, it is also known as the “heart” of the BEV.

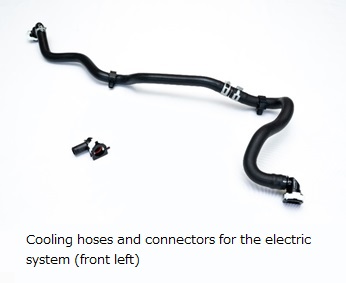

In regard to hoses, Toyota selected our “Electric System Cooling hoses”. Heat control is essential for suppressing electricity consumption, energy loss and battery degradation as much as possible. This has been an on-going issue for increasing cruising distance for BEVs. As such, effectively cooling all heat generating equipment with fluid (cooling water) inside the hoses keeps the temperature at the appropriate level and increases the efficiency of the entire system.

Finally, the sound controlling & insulation product Toyota selected was the new “eAxle cover” for the eAxle.

As the world heads towards a carbon neutral (CN) society by 2050, a new trend known as “CASE*” has surfaced in the automotive industry, and the electric “E” has been developing faster than the other elements. The Sumitomo Riko group has been making advancements in the development of all electric vehicles; namely, the HEV (hybrid electric vehicles), PHEV (plug-in hybrid electric vehicles) and BEV/FCEV (fuel cell electric vehicles).

As “a corporation that contributes to safety, comfort, and the environment for people, society, and the earth”, Sumitomo Riko group has successfully put products especially developed for BEV on the market with the view of further promoting BEVs. Through further technical development, we will contribute to the creation of a cleaner and more sustainable society, and a comfortable mobility life.

* (C:Connected) (A:Autonomous) (S:Shared & Services) (E:Electric)

Anti-vibration rubber (mount) has been newly developed to support front and rear wheel eAxle. It not only enhances comfort in the vehicle and increases the already superior drive response of BEVs, it has been designed to protect high voltage components in the eAxle in the event of an impact. The metal components contain a large amount of aluminum to ensure the mount is kept light-weight.

Anti-vibration rubber for suspension is a rubber that has had its composition, shape and performance tuned for the BEV-dedicated platform to absorb vibrations and shocks from the road surface while driving.

From the time of entering the automotive anti-vibration rubber market in 1954, we have applied the vibration control technology which we have developed and accumulated in all areas to gasoline engine vehicles, HEV, PHEV and FCEV to improve bZ4X comfort and driving stability.

Developed for the same platform, the optimum water hose module utilizes a water cooling format to cool the battery and other components of the electric system. The rubber hose and connector made of resin forms a cooling circuit to maintain the performance and optimize the efficiency of the motor, battery and all other components.

As BEVs require higher voltage batteries and a higher level of insulation for cooling fluid than convention vehicles, particular attention has been paid to anticipating the rare cases where cooling fluid might leak. Consequently, we have selected materials utilizing polymer materials technology (compound) to minimize cooling fluid becoming more conductive as a result of leaking from hoses and other structural components. We also simultaneously developed small light weight and space saving connectors.

The eAxle cover is the first sound insulation cover exclusively developed for the eAxle. This was achieved by applying sound insulation technology developed over many years for engine covers and gasoline vehicles to design technology with shaping flexibility particular to urethane material.

Installed at the bottom of the rear eAxle, the eAxle cover is effective against vibrations and noise across a broad range from low to high frequencies. As BEVs do not produce large vibrations and noise from the engine, sound from the eAxle and other units can conversely be more strongly felt. This product increases the in-vehicle comfort of passengers particularly in the rear seats.