Sumitomo Riko Company Limited (Headquarters: Nakamura-ku, Nagoya-shi; President & CEO: Kazushi Shimizu) will exhibit at a joint booth together with Sumitomo Electric Industries, Ltd. (Chuo-ku, Osaka-shi) and Sumitomo Wiring System, Ltd. (Yokkaichi-shi, Mie Prefecture) at the Automotive Engineering Exposition 2021 Online to be held from May 26 (Wed).

As the auto industry enters a period of major change, including the increase of electric vehicles (EV) and the acceleration of initiatives for “CASE*” to promote the advancement of technology for self-driving cars, Sumitomo Riko is actively engaged in the R&D of new products and materials utilizing our core competence, polymer materials technology and comprehensive evaluation technology.

At this online exhibition, we will show products of the Sumitomo Riko Group with a particular emphasis on “C: Connected” , “A: Autonomous” and “E: Electric”.

In the sensor field, we will show a “Film Decoration Ornament”, “Compartment Space Device” and the “Driver Monitoring System” as products to contribute to “C: Connected” and “A: Autonomous”.

In the thermal management field, we plan to show the “High Performance Heat Insulation: Finesulight™” and “Heat Insulation for Battery Cell” as products to contribute to “E: Electric”.

*「C:Connected」 「A:Autonomous」 「S:Shared & Services」 「E:Electric」

This is an ornament which can be used on exterior trims such as emblems and interior trim components. It is a unique type of film that can even be affixed on intricate and uneven surfaces. It is environmentally friendly as it requires less solvent than paint, and through the use of a special metallic film, it allows passage of radio waves and optical transmission and is suitable for millimeter-wave radar compatible emblems and illuminations. We are also in the process of developing an ornament with a built-in sensor by adding the film to an extendable sensor.

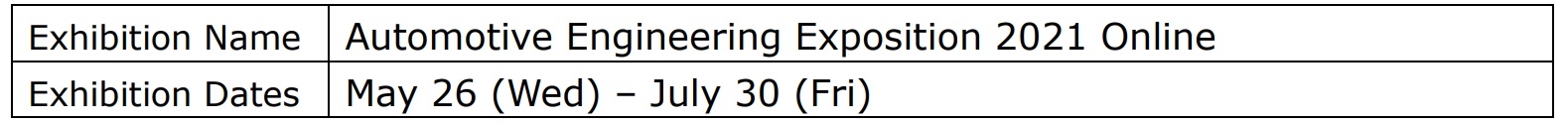

This compartment space device has been improved from the model previously displayed and now includes a switch that appears when the user wishes to operate the device. Its simple and functional design contributes to more intuitive use and comfortable mobility. A switch will appear when the user’s hand is detected near the detection area and this is operated by an internal flexible “Smart Rubber (SR) sensor”. It also contains a haptic interface that sends a vibrating a signal from the switch through an actuator made from Smart Rubber (SR), a special rubber that conducts electricity. Utilizing SR’s characteristics, SR can express various kinds of vibrations, such as strong and weak vibrations and different rhythms.

Made into the shape of a cushion, SR sensors are installed into the surface of the driver’s seat to detect the driver’s heart rate, breathing, body motion and other factors based on changes in pressure on the seat. The system estimates fatigue, drowsiness, signs of sudden illness and other conditions from the observed data and can connect to services such as alerting the driver, generating the driving support system or sending an external notification.

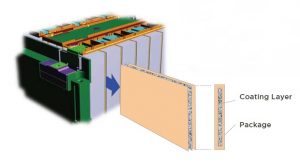

Utilizing polymer materials technology, we made a high-heat insulating filler (silica aerogel) containing nanopores small enough to block the passage of air, into a coating liquid. Then, by coating base materials such as non-woven fabric and molded resin at a level of still air or higher. As mobility moves toward electric vehicles (EV), all energy needs to be supplied by electricity. As such, this product increases the effectiveness of cooling and heating and contributes to extending cruising distance. In addition to use in vehicles, we anticipate that this can be used in various fields including household appliances, housing and food delivery.

We have improved the Finesulight™ compound bonder technology and developed an insulator for lithium-ion batteries in electric vehicles (EV) which can withstand high temperatures of several hundred degrees celsius. It suppresses heat chains from developing between adjacent cells in the case of extraordinary heat surges and avoids major incidents which can cause fires in the vehicle. We aim to optimize this insulator by making further adjustments to the insulation performance, hardness and other factors in line with customer requirements.