SUSTAINABILITY

Global Excellent Manufacturing CompanyGlobal Excellent Manufacturing Company

SUSTAINABILITY NEWS

-

2024/03/26

Sumitomo Riko increases Solar Power Generation by 1.6 fold across the Group in FY2023 ~Solar Power Generation Facilities to be Installed at Seven Global Bases~ -

2023/07/31

Renewal of Sustainability Website (this site) -

2023/05/30

The formulation of “2029 Sumitomo Riko Group Vision” and “2025 Sumitomo Riko Group Mid-term Management Plan” -

2022/11/22

Sumitomo Riko and LanzaTech enter into a joint-development agreement to reuse rubber, resin, and urethane waste, contributing to the creation of a circular economy -

2022/08/09

Announcing Membership in the GPSNR for Sustainable Natural Rubber -

2022/06/24

Announcing Sumitomo Riko’s Commitment to the Task Force on Climate-related Financial Disclosures (TCFD) Recommendations

Our Philosophy

Sustainability Management

We will continue to grow while meeting the expectations of society and co-creating with our stakeholders toward the realization of a sustainable society. Here is our framework for this purpose.

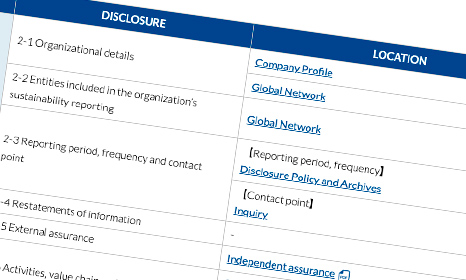

Sustainability Activities

Here we explain our approaches to "E: Natural Environment," "S: Social Environment," and "G: Management Structure," which are indispensable for sustainable corporate growth.

E

Environment

Environment (E)

- Long-Term Environmental Vision and Environment 2029V

- Environmental Management

- Responding to Climate Change

- Responding to Water Risks

- Contributing to a Recycling-Oriented Society

- Contributing to a Society in Harmony with Nature

- Appropriate Management of Chemical Substances

- Environmental Communication

- Environmentally Conscious Products